|

|

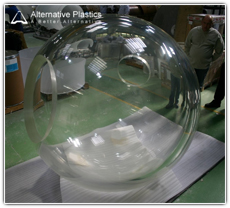

Case Study 3: Submarine Window

Last month we helped one of our customers with a project to build a submarine sphere. Our customer had cast & prepared the large acrylic sphere in two halves but asked us to structurally bond the two halves together. Using a very special resin, we carried out testing in advance to ensure we knew how the new chemical would behave.

The two halves were set in a frame and then carefully aligned before setting up and pouring the bond. Due to the testing we had done before, we were able to achieve perfect results and avoid bubbles forming. The bond went perfectly leaving a perfect structural bond.

The customer then took the sphere back where they removed the excess resin and polished the sphere. It was then annealed before being delivered to the end customer. The end customer was very happy and has tested the sphere to a pressure depth of 360 metres! |

Case Studies   Last month we helped one of our customers with a project to build a submarine sphere. Our customer had cast the acrylic sphere in two halves but asked us to structurally bond the two halves together. More... In March 07 we delivered 11 tons of acrylic for 92 free standing & wall mounted directional signs for a new wayfinding system at Selfridges, for their Oxford Street store. More... |

|

0

Your Basket

All items selected from our product lists will be added here

You may request a quote or enquire about products or services not listed |